Views: 0 Author: Site Editor Publish Time: 2025-11-05 Origin: Site

Ever wondered how plastic products achieve their precise shapes? The key lies in the Plastic extruder gearboxs. This vital component transforms motor power into the force needed for plastic extrusion. In manufacturing, it ensures consistency, efficiency, and quality. In this post, you'll learn about its functions, types, and impact on production.

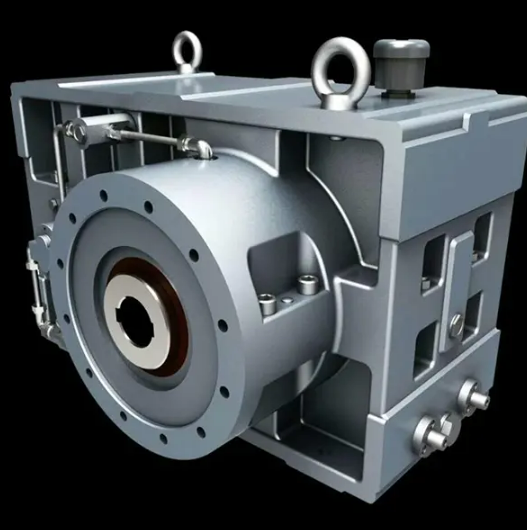

A plastic extruder gearbox is a mechanical device designed to transfer power from the motor to the extruder screw. It converts the motor’s high-speed rotation into a lower speed, higher torque output necessary for pushing molten plastic through a shaping die. This process enables the plastic to be formed into various products like pipes, sheets, or profiles.

The gearbox controls speed and torque, ensuring the screw rotates at the right pace and force for consistent extrusion. It also allows for reversing screw rotation when needed, which helps in cleaning or changing materials. Without this component, the extruder would lack the precision and power required for effective plastic shaping.

Unlike general industrial gearboxes, plastic extruder gearboxes are specially designed to handle unique stresses. For example:

● Thrust Load Handling: Extruder gearboxes include thrust or tandem bearings on the output shaft to support axial forces generated by the screw pushing plastic material.

● Speed Reduction and Torque Amplification: They reduce motor speed while increasing torque, a combination not always emphasized in standard gearboxes.

● Durability Under Continuous Operation: These gearboxes are built to withstand long hours of continuous operation under heat and pressure conditions typical in plastic extrusion.

Standard gearboxes might not have these specialized features, making extruder gearboxes essential for plastic manufacturing.

Feature | Plastic Extruder Gearbox | Standard Industrial Gearbox |

Thrust Bearing | Included for axial load support | Often absent or minimal |

Speed Reduction | Significant and precise | Variable, often less precise |

Torque Amplification | High, to push molten plastic | Depends on application |

Operation Conditions | Continuous, high heat and pressure | Varies, often intermittent |

Reversibility | Commonly supported for process flexibility | Not always available |

This comparison highlights why extruder gearboxes are tailored to the demands of plastic extrusion processes.

The primary role of a plastic extruder gearbox is to transmit power from the motor to the extruder screw. The motor generates rotational energy at high speeds, but the screw needs to turn slower and with more force. The gearbox acts as a translator, converting this high-speed rotation into a slower, more powerful motion. This power transmission is crucial because it drives the screw that pushes molten plastic through the shaping die, enabling the creation of various plastic products.

Plastic extrusion demands high torque to push thick, molten plastic through tight dies. The gearbox amplifies the torque produced by the motor, increasing the force applied to the screw. This amplification ensures the screw can overcome resistance within the extrusion barrel and maintain consistent pressure. Without sufficient torque, the extrusion process would stall or produce inconsistent products. Torque amplification also helps in handling variations in material viscosity and extrusion speed, keeping the process stable.

Different plastic products require different extrusion speeds. The gearbox provides precise speed control by reducing the motor’s rotation speed to the optimal level for the extrusion process. This regulation allows manufacturers to fine-tune the screw’s speed to match the material type, product design, and production requirements. Proper speed control helps achieve uniform product dimensions, reduces defects, and improves overall quality. It also allows the extruder to adapt quickly to changes in production demands.

Some extrusion processes need the ability to reverse the screw’s rotation. This reversibility is essential for clearing blockages, purging old material, or switching between different plastic compounds. The gearbox enables this function by allowing controlled reverse rotation of the screw. It adds flexibility to the extrusion process, making maintenance easier and reducing downtime. Reversibility is especially important in twin-screw extruders, where precise control over screw movement impacts mixing and compounding efficiency.

A plastic extruder gearbox is made up of several vital parts, each playing a key role in its operation. Understanding these components helps in selecting the right gearbox and maintaining it for optimal performance.

The input shaft connects directly to the motor, receiving its high-speed rotation. This shaft carries power inside the gearbox. The output shaft transfers the converted power from the gearbox to the extruder screw. It rotates at a lower speed but with much higher torque, pushing the molten plastic through the die. Both shafts must be precisely aligned and supported to avoid vibration and wear.

The gear set is the heart of the gearbox. It consists of interlocking gears of different sizes and tooth counts. These gears reduce the motor's speed and increase torque. The gear ratio determines how much speed is reduced and torque amplified. High-quality gears are made from durable materials and manufactured with precision to ensure smooth power transmission and long service life.

Bearings support the shafts and gears, allowing them to rotate smoothly and handle radial and axial loads. Proper lubrication is critical to reduce friction and prevent overheating. Gearboxes often have oil baths or forced lubrication systems to keep bearings and gears well-lubricated during continuous operation. This maintenance extends the gearbox’s life and prevents costly breakdowns.

Plastic extruder screws generate significant axial forces as they push molten plastic forward. Thrust bearings or tandem bearings are specially designed to absorb these axial loads on the output shaft. Without these bearings, the gearbox would suffer rapid wear or failure. Tandem bearings are often used in heavy-duty extruders for extra load support and increased reliability.

Plastic extruder gearboxes come in various types, each designed to meet specific manufacturing needs. The two main categories are single-screw extruder gearboxes and twin-screw extruder gearboxes. Understanding their differences and applications helps manufacturers choose the right gearbox for their processes.

The single-screw extruder gearbox is the most common type used in plastic manufacturing. It powers a single rotating screw that melts and pushes plastic through a die. These gearboxes are known for their simplicity, durability, and cost-effectiveness.

● Applications: They are widely used for producing pipes, sheets, profiles, and films. Single-screw extruders excel in straightforward extrusion tasks where uniform melting and shaping are required.

● Advantages: Easier maintenance, lower initial costs, and reliable performance in continuous operation.

● Limitations: Less effective for mixing or compounding materials compared to twin-screw systems.

Twin-screw extruder gearboxes drive two screws, which can rotate either in the same direction (co-rotating) or opposite directions (counter-rotating). This design offers enhanced control over mixing, melting, and conveying of plastic materials.

● Co-rotating Twin-Screw Gearbox: Both screws rotate in the same direction, providing excellent mixing and compounding capabilities. This type is often used in producing masterbatches, composites, and specialized plastic compounds.

● Counter-rotating Twin-Screw Gearbox: Screws rotate in opposite directions, offering high torque and pressure. This setup is suitable for producing pipes, sheets, and profiles requiring strong material consistency.

● Advantages: Superior mixing, better handling of complex materials, and flexibility in processing.

● Limitations: Higher cost and more complex maintenance compared to single-screw gearboxes.

Each gearbox type suits particular manufacturing processes depending on product requirements:

● Single-Screw Gearboxes: Ideal for high-volume production of simple plastic products like films, sheets, and pipes.

● Twin-Screw Gearboxes: Preferred for products needing precise mixing, such as plastic compounds, masterbatches, and recycled materials.

● Specialized Uses: Twin-screw gearboxes are essential in industries like medical device manufacturing and 3D printing, where material consistency and quality are critical.

A plastic extruder gearbox plays a vital role in maintaining consistency during the extrusion process. By precisely controlling the screw's speed and torque, it ensures that molten plastic flows steadily through the die. This steady flow helps produce products with uniform dimensions and surface finish. Without consistent speed and torque, the extrusion process can suffer from fluctuations, leading to defects like uneven thickness, bubbles, or weak spots.

For example, when manufacturing plastic pipes, any variation in extrusion speed can cause wall thickness inconsistencies, affecting the pipe's strength and durability. The gearbox helps prevent such issues by delivering stable power and smooth operation. This consistency is crucial in industries like medical device manufacturing or automotive parts, where product quality directly impacts safety and performance.

Efficient gearboxes reduce energy consumption by optimizing power transmission between the motor and the extruder screw. By minimizing energy losses in the gearbox, manufacturers can lower operational costs and reduce their carbon footprint. High-quality gearboxes with precision gears and effective lubrication systems generate less heat and friction, which also extends the equipment’s lifespan.

Moreover, energy-efficient gearboxes help maintain steady extrusion conditions, reducing waste caused by defective products. This means fewer raw materials are discarded, leading to cost savings. In large-scale operations, even small improvements in gearbox efficiency can translate into significant financial benefits over time.

The gearbox impacts the ability to meet specific product requirements, such as size, shape, and mechanical properties. By allowing precise control over extrusion speed and torque, it enables manufacturers to fine-tune the process for different materials and product designs. For instance, some plastics require slower extrusion speeds to avoid overheating, while others need higher torque to push through complex dies.

Additionally, gearboxes that support reversible operation help manufacturers switch between materials or clean the system without lengthy downtime. This flexibility is essential for producing customized products or small batches with varying specifications. Ultimately, the gearbox’s performance influences the quality, reliability, and versatility of the final plastic products.

Plastic extruder gearboxes face several wear and tear challenges due to the demanding conditions they operate under. The continuous high torque and thrust loads cause stress on gears and bearings. Over time, gear teeth may wear down or chip, leading to inefficient power transmission and increased noise. Bearings, especially thrust and tandem types, can suffer from fatigue or damage, resulting in misalignment or vibration.

Thermal stress from prolonged operation at elevated temperatures can degrade lubrication quality, accelerating wear. Contaminants like dust or plastic particles may enter the gearbox housing, causing abrasion and corrosion. Seal failure can lead to lubricant leaks, further risking damage. These issues often manifest as unusual noises, overheating, or reduced extrusion quality.

Regular maintenance is crucial to extend gearbox life and ensure consistent extrusion performance. Routine inspections help detect early signs of wear, such as abnormal sounds, vibration, or temperature spikes. Checking lubricant levels and quality prevents friction-related damage. Timely replacement of worn bearings and seals avoids costly breakdowns.

Scheduled cleaning removes contaminants and prevents buildup that can impair gear meshing. Proper alignment checks of input and output shafts reduce stress on components. Lubrication systems should be maintained or upgraded to ensure adequate cooling and friction reduction. A proactive maintenance plan minimizes downtime, reduces repair costs, and maintains product quality.

When repairs are necessary, selecting the right solutions is vital. Repairs should restore the gearbox to original specifications to maintain performance and reliability. Skilled technicians use precision machining to refurbish gears and shafts, ensuring proper tooth profiles and alignment.

Bearing replacements must match OEM specifications, considering load capacity and operating conditions. Upgrading seals and lubrication systems can improve longevity. Some repairs may involve retrofitting improved components or materials for enhanced durability.

Choosing a repair provider with expertise in extruder gearboxes ensures tailored solutions that address specific wear patterns. Comprehensive testing after repair confirms gearbox functionality under load. Investing in quality repairs reduces the risk of repeated failures and supports continuous production.

A plastic extruder gearbox transfers power from the motor to the extruder screw, converting high-speed rotation into lower speed, higher torque. It ensures consistent extrusion, precise speed regulation, and reversibility for maintenance. These gearboxes are essential in plastic manufacturing due to their durability under continuous operation. As technology advances, future gearboxes will likely offer enhanced energy efficiency and control features. For reliable and high-quality extruder gearboxes, consider Dawang for their exceptional product benefits and dedicated services.

A: A Plastic Extruder Gearbox is used to transmit power from the motor to the extruder screw, converting high-speed rotation into slower, higher torque motion necessary for effective plastic extrusion.

A: It ensures consistent extrusion by precisely controlling screw speed and torque, leading to uniform product dimensions and reducing defects like uneven thickness or weak spots.

A: Regular maintenance prevents wear and tear, ensuring efficient power transmission and prolonging gearbox life, reducing downtime and repair costs.

A: Costs depend on gearbox type, size, and features like thrust bearings and speed regulation. High-quality gearboxes may have higher initial costs but offer long-term savings through efficiency and durability.

A: Unlike standard gearboxes, Plastic Extruder Gearboxes handle unique stresses like thrust loads, offer precise speed reduction, and are designed for continuous operation under high heat and pressure.