Views: 0 Author: Site Editor Publish Time: 2025-09-24 Origin: Site

Plastic extrusion is one of the most widely used manufacturing processes in the modern industrial world. From producing pipes and films to sheets and profiles, extrusion plays a central role in shaping the plastics that surround us in everyday life. While much of the attention in extrusion often goes to materials, die design, and heating systems, one crucial component tends to be overlooked: the Plastic Extruder Gearbox.

Behind the scenes, the gearbox acts as the backbone of the extrusion process, converting motor power into the torque and speed required to operate the screw efficiently. Its role is not only mechanical but also directly impacts productivity, product quality, and the overall efficiency of extrusion operations. In this article, we will explore why gearbox design is so critical to modern plastic extrusion technology and how advancements in this area contribute to better outcomes across the plastics industry.

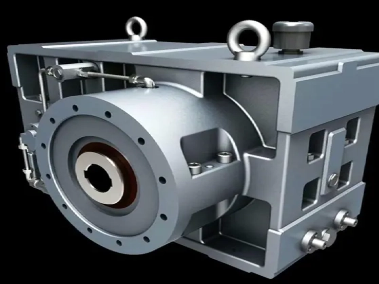

At its core, a plastic extruder gearbox is a specialized power transmission system designed to reduce motor speed while increasing torque, which is then transferred to the screw inside the extruder barrel. This balance of torque and speed is essential because plastic materials require substantial force to be melted, mixed, and pushed through the extrusion die.

Key functions of the extruder gearbox include:

Speed Reduction: Electric motors typically run at high rotational speeds that are unsuitable for extrusion screws. The gearbox reduces this speed to an optimal level.

Torque Multiplication: Extrusion requires high torque to process plastics effectively. Gearboxes amplify the torque to match extrusion demands.

Load Distribution: The gearbox distributes mechanical loads evenly, reducing wear and tear on both the motor and the extrusion screw.

Operational Stability: By ensuring consistent torque and speed, gearboxes enable stable, continuous extrusion, critical for producing uniform products.

Without a properly designed gearbox, even the most advanced extruder would struggle to function efficiently.

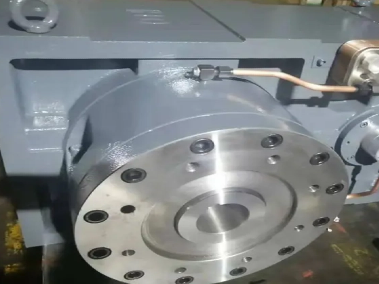

Plastic extrusion is a demanding process that subjects components to high stress and continuous operation. A well-designed gearbox must withstand not only mechanical loads but also high temperatures and long operating hours. Advanced gear geometry, surface treatments, and material selection are essential to prevent premature wear or catastrophic failures.

Gearbox design influences how efficiently motor energy is converted into extrusion output. Precise gear meshing reduces energy loss, minimizes vibration, and ensures smoother operation. In an industry where energy costs account for a large share of production expenses, gearbox efficiency translates directly into cost savings.

Poorly designed gearboxes may generate excessive noise and vibration, which not only impact workplace comfort but also shorten the lifespan of the entire extrusion system. Modern gearbox designs incorporate optimized tooth profiles, lubrication systems, and housings to minimize these issues.

Extrusion is not a one-size-fits-all process. Depending on whether the machine is producing pipes, films, or profiles, torque and speed requirements vary. Gearbox design must be adaptable, offering ratios and configurations that suit specific extrusion tasks.

Modern plastic extrusion has pushed gearbox design into new frontiers. Some notable advancements include:

High-Torque Density Gearboxes: These designs allow for higher torque output without increasing the gearbox size, saving space and improving machine compactness.

Improved Cooling Systems: Since extrusion often involves continuous operation, heat buildup can damage gears. Advanced cooling technologies, including oil circulation and jacketed housings, maintain optimal operating temperatures.

Precision Manufacturing: Computer-aided design (CAD) and CNC machining have improved gear accuracy, reducing backlash and improving performance.

Lubrication Optimization: Modern synthetic lubricants and intelligent lubrication systems reduce friction, enhance energy efficiency, and extend component life.

Condition Monitoring: Some advanced gearboxes now integrate sensors that monitor temperature, vibration, and load, enabling predictive maintenance and reducing downtime.

These innovations collectively enhance reliability, extend service life, and reduce the total cost of ownership for extrusion equipment.

The role of the gearbox extends beyond machinery performance—it also influences the quality of the final plastic products.

Consistency in Output: A stable gearbox ensures that the screw rotates at a constant speed, preventing fluctuations in melt flow and product dimensions.

Improved Material Homogeneity: High torque and precise control allow the screw to mix raw materials more thoroughly, improving product uniformity.

Reduced Defects: Variations in speed or torque can cause surface imperfections, dimensional inconsistencies, or internal stresses in extruded products. Reliable gearbox performance minimizes these risks.

Support for High-Performance Materials: Advanced polymers, composites, and additives often require tighter processing control. A modern gearbox enables extruders to handle these demanding materials effectively.

In industries such as packaging, construction, and automotive manufacturing, where precision and reliability are non-negotiable, the gearbox is a silent contributor to quality assurance.

Investing in a high-quality plastic extruder gearbox may involve higher upfront costs, but the long-term economic benefits far outweigh the initial expense.

Energy Savings: Efficient gearboxes reduce power consumption, cutting electricity bills significantly.

Reduced Maintenance Costs: Durable components and optimized designs lower repair frequency and parts replacement costs.

Minimized Downtime: A reliable gearbox keeps the extrusion line running smoothly, avoiding costly production interruptions.

Extended Equipment Lifespan: By reducing stress on screws, motors, and bearings, gearboxes extend the lifespan of the entire extrusion system.

Ultimately, well-designed gearboxes contribute to higher productivity and better profitability, making them a wise investment for extrusion businesses.

While the importance of gearbox design is clear, selecting the right gearbox for a plastic extruder can be challenging. Considerations include:

Torque and Speed Requirements: Choosing a gearbox with the correct reduction ratio for the application.

Material Compatibility: Ensuring the gearbox materials and lubrication systems are suited to the extrusion environment.

Load Cycles: Understanding whether the extrusion process involves continuous loads or fluctuating stresses.

Space and Integration: Matching gearbox dimensions with machine layout constraints.

Supplier Reliability: Working with reputable manufacturers who can provide technical support and customization.

Selecting the wrong gearbox can result in inefficiency, frequent breakdowns, and poor product quality. Hence, careful evaluation and collaboration with experienced suppliers are essential.

Looking ahead, gearbox technology is expected to evolve further alongside broader industry trends:

Sustainability: Gearbox designs will increasingly focus on minimizing energy losses and supporting greener manufacturing processes.

Smart Technology Integration: The use of IoT-enabled monitoring systems will grow, allowing predictive maintenance and real-time performance tracking.

Compact, High-Power Designs: With industries demanding higher output from smaller machines, gearboxes will continue to become more compact while delivering higher torque.

Customization: Extrusion manufacturers will seek gearboxes tailored to specific product requirements, driving demand for customized solutions.

These developments will cement the gearbox’s role as a cornerstone of extrusion technology innovation.

In the world of plastic extrusion, the gearbox may not always be in the spotlight, but its role is indispensable. A well-designed Plastic Extruder Gearbox ensures that machines run efficiently, materials are processed consistently, and final products meet exacting standards. Advances in gearbox technology continue to enhance performance, reduce costs, and enable the industry to meet the growing demand for precision, efficiency, and sustainability.

For businesses seeking reliable and advanced gearbox solutions, it is essential to work with trusted suppliers who understand the intricacies of extrusion technology. Companies like Suzhou Dawang Transmission Equipment Co., Ltd. specialize in high-performance gearboxes for plastic extrusion, offering expertise, quality, and tailored solutions to meet industry needs. Exploring their products and services can be a valuable step for manufacturers aiming to improve extrusion performance and ensure long-term success.