Views: 0 Author: Site Editor Publish Time: 2025-09-24 Origin: Site

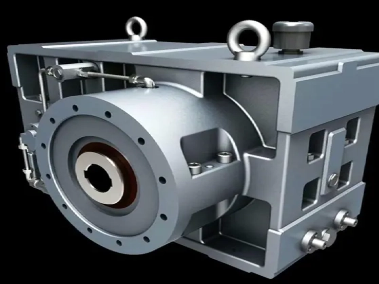

In the world of plastic processing, efficiency, precision, and durability are essential for achieving high-quality output while keeping operational costs under control. At the heart of every extrusion line lies one of the most critical components—the plastic extruder gearbox. This gearbox serves as the power transmission system that ensures torque, speed, and stability are delivered consistently to the extruder screw.

While extruder gearboxes have been around for decades, modern advances in design and engineering have given rise to high-efficiency gearboxes that offer remarkable advantages over older, conventional systems. These innovations are transforming the way plastic manufacturers operate by reducing energy consumption, extending equipment life, and enhancing overall performance.

Energy costs are among the most significant expenses in plastic manufacturing plants. A high-efficiency plastic extruder gearbox is designed to minimize energy loss during power transmission, ensuring that a greater percentage of input energy is converted into useful mechanical work.

Key features contributing to energy efficiency include:

Precision-cut gears that reduce frictional losses.

High-quality lubrication systems that ensure smooth operation.

Improved alignment and load distribution to avoid unnecessary resistance.

The result is lower energy consumption, which not only reduces operating costs but also supports sustainability goals by cutting carbon emissions. For companies aiming to improve energy efficiency across their production lines, upgrading to a high-efficiency gearbox is one of the most impactful changes they can make.

Plastic extrusion requires consistent, high torque to melt, mix, and push materials through the die. High-efficiency extruder gearboxes are engineered to deliver greater torque density, allowing for smooth and powerful operation even under high loads.

Advanced gear geometry and reinforced materials provide:

Stable torque output across varying load conditions.

Improved handling of viscous or tough polymer materials.

Reduced risk of slippage or torque fluctuation.

This stability is critical for producing consistent plastic products, whether sheets, films, pipes, or profiles, and for meeting the tight tolerances required by modern applications.

A gearbox is not only a major financial investment but also a critical link in the production chain. When a gearbox fails, the entire extrusion line may come to a halt, leading to costly downtime, missed delivery deadlines, and additional labor expenses. High-efficiency extruder gearboxes are specifically designed with long-term durability in mind, ensuring that manufacturers can operate continuously with fewer interruptions.

Several design features contribute to their extended lifespan:

Advanced metallurgy and heat treatment: The gears and shafts are manufactured using high-grade alloy steels and undergo precise heat treatment processes. This significantly improves resistance to wear, surface fatigue, and micro-cracking, which are common causes of early gearbox failure.

Optimized heat dissipation: Continuous extrusion generates considerable amounts of heat. High-efficiency gearboxes incorporate specialized cooling systems, optimized housing designs, and efficient lubrication circulation to prevent overheating. Stable operating temperatures reduce thermal stress on internal components.

High-load-bearing capacity: Reinforced bearings and gear geometry distribute stress evenly, minimizing the risk of pitting, scuffing, or gear tooth deformation under heavy loads. This is particularly valuable when processing viscous polymers that demand greater torque.

Precision assembly and alignment: Misalignment within a gearbox can accelerate wear and cause vibration. High-efficiency gearboxes are manufactured to exacting tolerances, ensuring smooth meshing and longer component life.

Durability is only part of the equation; ease of maintenance is equally important for modern extrusion plants. High-efficiency gearboxes are engineered not only to last longer but also to be simpler to service, minimizing the disruptions caused by routine upkeep.

Key features that reduce maintenance demands include:

Modular design: Many high-efficiency extruder gearboxes are built with modular structures, allowing individual components—such as bearings, seals, or lubrication systems—to be replaced without dismantling the entire unit. This reduces both repair time and the likelihood of human error during servicing.

Simplified access points: Inspection ports, oil level gauges, and strategically placed openings make it easier for technicians to check lubrication conditions, inspect gears, and perform preventive maintenance tasks without extended downtime.

Advanced lubrication systems: Automatic or semi-automatic lubrication mechanisms ensure a consistent supply of lubricant to critical components, reducing the risk of insufficient lubrication—a common cause of gearbox damage.

Condition monitoring compatibility: Many modern gearboxes are designed to integrate with vibration sensors, temperature monitors, and IoT-based predictive maintenance tools. This allows real-time monitoring of gearbox health, enabling early detection of wear or abnormal conditions before they escalate into serious failures.

The benefits of simplified maintenance are tangible:

Shorter service intervals mean extrusion lines spend less time offline.

Lower labor costs arise from faster maintenance procedures and reduced reliance on specialized external technicians.

Improved reliability results from better monitoring, preventive care, and reduced likelihood of unexpected breakdowns.

Older gearbox designs are often noisy and prone to vibrations, which can cause operator fatigue, reduced workplace safety, and even product defects due to instability. High-efficiency extruder gearboxes are carefully engineered to operate quietly and smoothly, thanks to advanced machining processes, precise gear meshing, and vibration-damping materials.

A high-efficiency gearbox contributes directly to the consistency and quality of plastic products. By maintaining steady torque and speed control, it ensures that polymers are melted and extruded uniformly. This stability results in:

Accurate product dimensions with fewer defects.

Improved surface finish for films and sheets.

Better material homogeneity, especially important in applications requiring strong mechanical properties.

Modern high-efficiency plastic extruder gearboxes are often designed to be more compact than older models. This allows manufacturers to save space on the production floor while still achieving high performance. The flexibility in design also makes it easier to integrate these gearboxes into both new extrusion lines and retrofit projects, giving manufacturers greater versatility.

While high-efficiency extruder gearboxes may involve higher upfront costs compared to standard gearboxes, they quickly prove their value through:

Lower energy bills due to improved efficiency.

Reduced downtime from fewer breakdowns and easier maintenance.

Extended equipment life, minimizing replacement expenses.

Higher product quality, reducing scrap and rework costs.

Sustainability has become a priority across the plastics industry, driven by customer demand and regulatory pressures. High-efficiency gearboxes support these goals by:

Reducing energy consumption and lowering greenhouse gas emissions.

Enabling more efficient use of raw materials through improved product consistency.

Extending equipment life, thereby reducing waste from prematurely discarded machinery.

As manufacturing evolves, extrusion processes are becoming more complex, often requiring advanced control systems, higher throughput, and the ability to process a wider range of materials. High-efficiency gearboxes are engineered to support these demands, offering:

Compatibility with automation and smart monitoring systems.

The ability to handle high-performance polymers with demanding extrusion requirements.

Scalability to meet increasing production volumes.

The plastic extruder gearbox may not always be the most visible component in an extrusion line, but its role is absolutely vital. High-efficiency gearboxes provide a wide range of advantages, from reducing energy costs and extending lifespan to improving product quality and supporting sustainability goals.

For manufacturers looking to improve productivity, lower operating expenses, and ensure consistent performance, upgrading to a high-efficiency gearbox is a sound investment.

If you are considering reliable, high-quality gearbox solutions for your extrusion lines, Suzhou Dawang Transmission Equipment Co., Ltd. is a trusted partner in the field. With expertise in designing and manufacturing durable, high-performance gearboxes, they can provide tailored solutions to meet your production needs. To learn more, you can visit www.dawanggearbox.com or contact their team for professional guidance.